Vacuum Dehydration or Purifier Systems

There are many methods of removing water, but only one can effectively remove all three phases, i.e. dissolved, emulsified or free-water.

Water removal, Purifiers, Vacuum Dehydrators, or whatever the name, are all linked to the use of Vacuum Dehydration: The ability to heat the oil in a vacuum without affecting its properties and boiling off all the aforementioned three phases of water in oil.

Vacuum Dehydration Systems offer the perfect balance of heat, vacuum, process design to create an easy and user-friendly way to remove water and particulate from hydraulic, high viscosity lubricating and insulating oils.

Keeping lubricants clean and water-free extends component and bearing life, increases productivity, minimizes downtime and extends useful fluid life.

How it Works

Courtesy of Hy-Pro Filtration

The purification system is designed to remove water (all three phases), solid particulate and dissolved gasses from petroleum and synthetic industrial oils. The water removal principle used is simple, reliable and will remove water well below the oil's saturation point, even when tightly bound in emulsion.

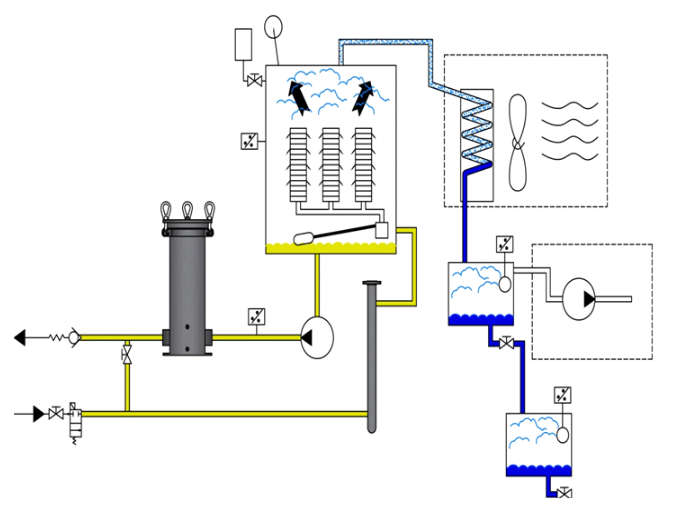

The schematic displayed to the left and below shows a typical Vacuum Dehydration System.

The vacuum pump creates a vacuum that draws the industrial oil into the unit through an in-line heater, and it is then heated up to 66°C (150°F). It then flows through specially designed dispersal elements located inside the vacuum tower. The resulting thin oil film flowing across the dispersal elements and exposed to the vacuum, normally set at 635 mmHg (25 inHg), vapourises the water.

Because the boiling point of water under vacuum is below the set oil temperature, it is left dehydrated or dry without affecting its ‘clean oil’ properties. An outlet pump subsequently takes the oil from the bottom of the vacuum chamber and pumps it through a high-efficiency glass media particulate filter and back into the equipment reservoir. The water vapour is drawn via a condenser, liquifies and drains into the condensate tanks.

Courtesy of Hy-Pro Filtration

The Vacuum Dehydration system's mechanical components require little or no routine maintenance, making the unit very reliable. All components can be field repaired or replaced without special tools.

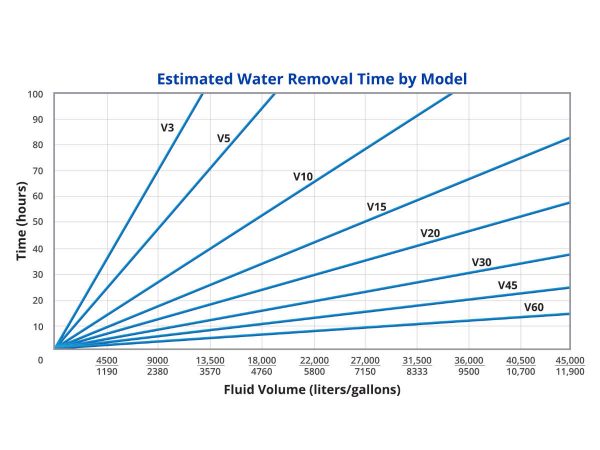

To the left is a guide for the VUD Vacuum Dehydration systems estimated removal rate.

Custom Engineered Systems

Get in touch if you have a special requirement. We readily take on challenges and deliver a quality product with professional pre-and-post technical support and impressive proven customer success.

See our Dredging Grab Bucket application in the resources section.