A Good and Effective Oil Analysis Program Includes these Actions:

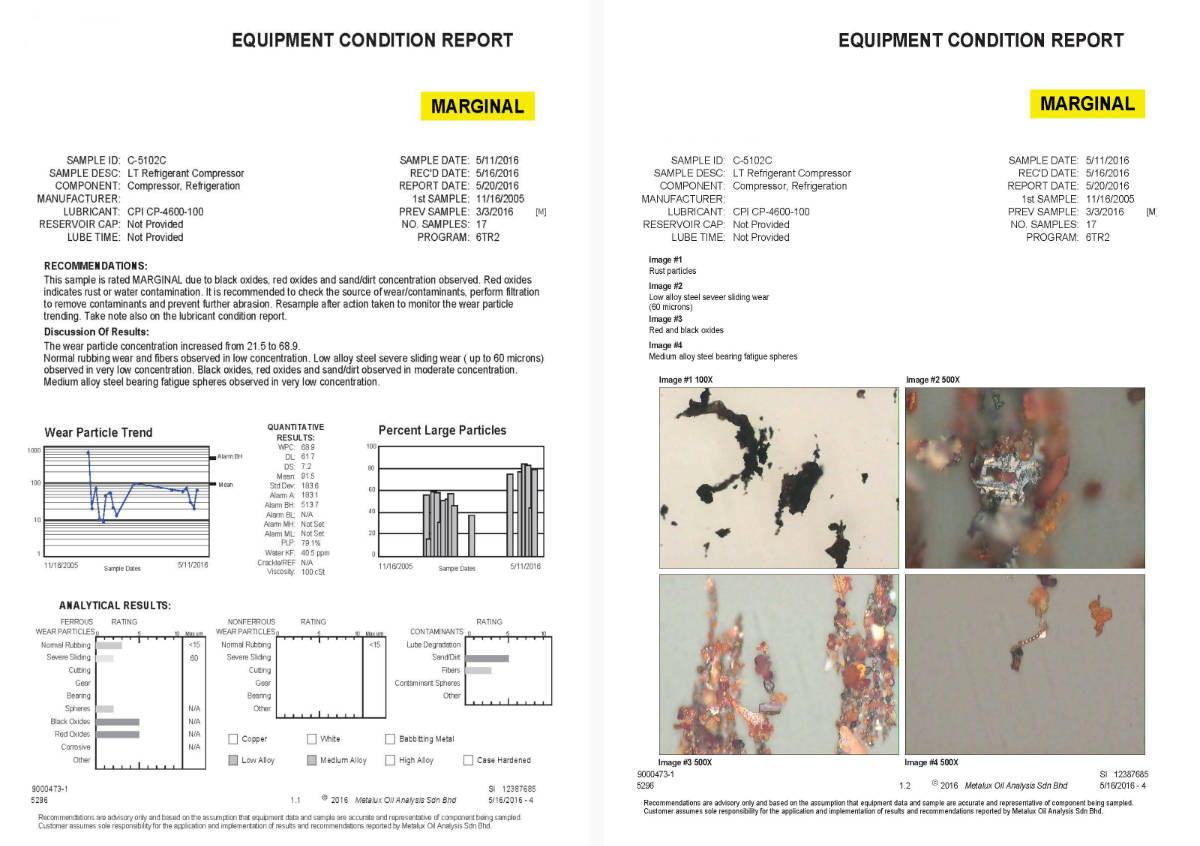

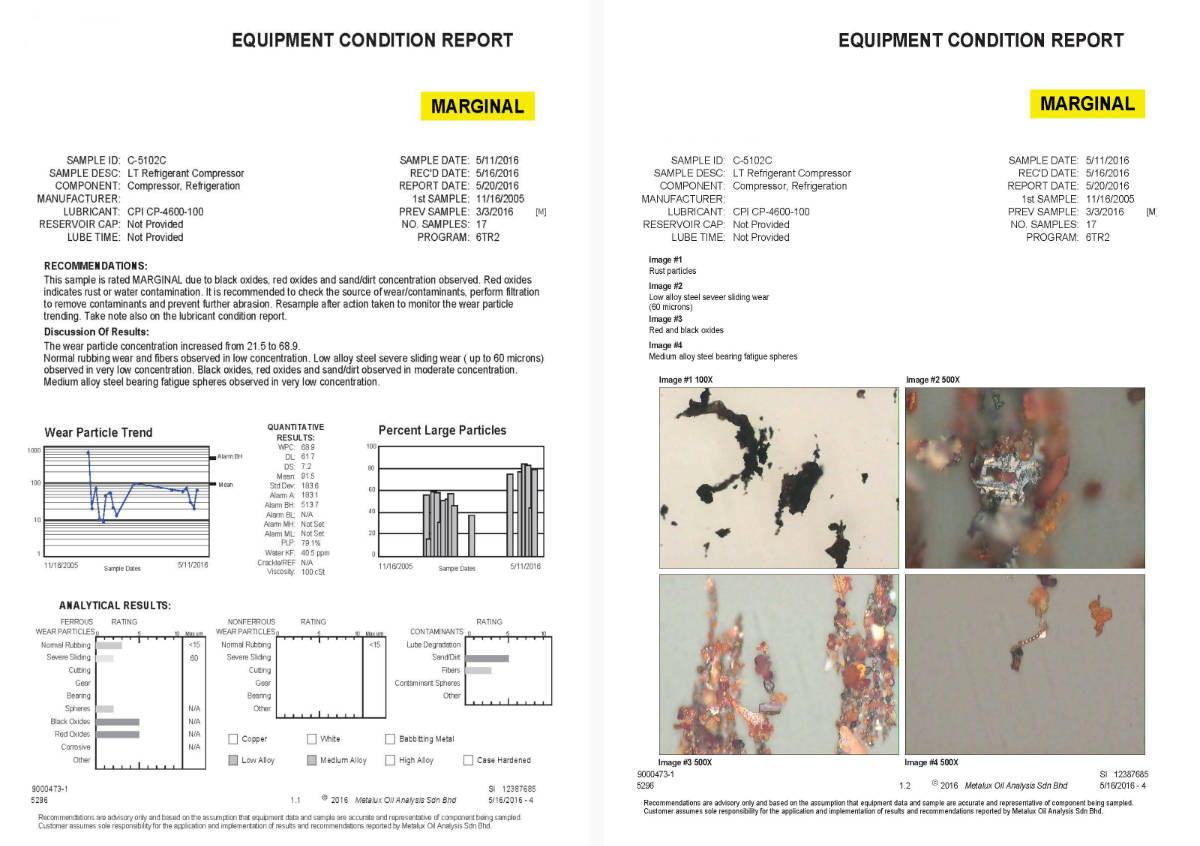

Determine the Health of the Lubricating Oil and the Condition of the Machine

Correct oil sampling practices and procedures to extract the most information about the health of the lubricating oil and the condition of the machine. Below is an example of oil analysis report:

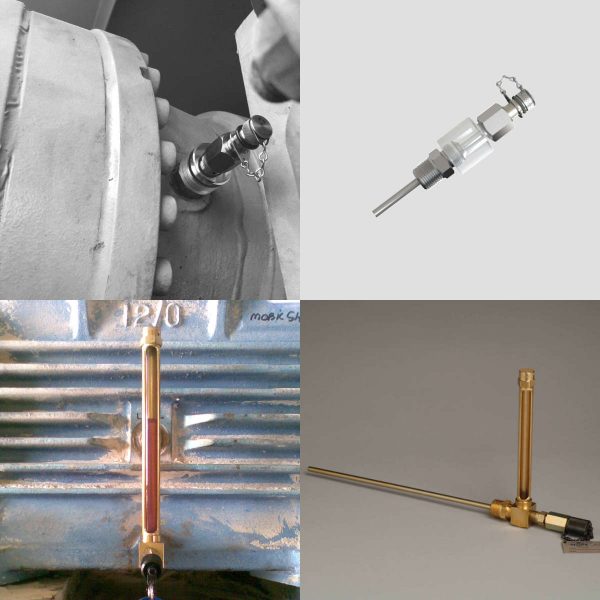

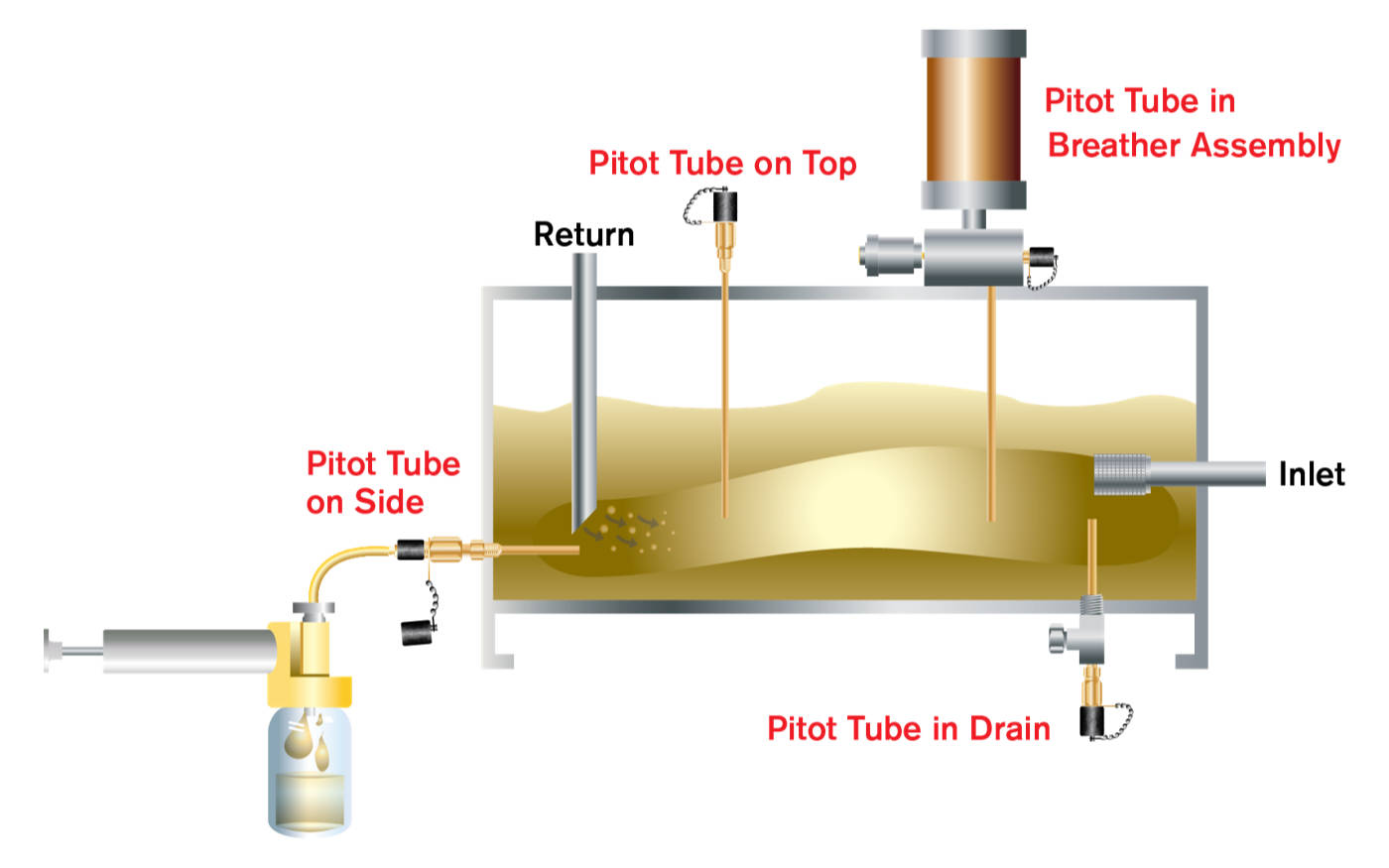

Use Appropriate Sampling Points

Isolate & Extract Samples Safely with Sample Equipment

Manage Records and Track Interaction with Equipment

It is important that all Interaction with equipment is recorded, e.g:

- Oil drains

- Oil top-ups

- Shut-downs

- Bearing failures

- Seal failures

Review Lube Oil Analysis Report Trends

Review of the Lube Oil Analysis report against its trend or previous reports is also of paramount importance to the right and effective decision for any corrective action required.